The Basic Principles Of Roof Nuts

Table of ContentsRoof Nuts Can Be Fun For EveryoneRoof Nuts Can Be Fun For EveryoneThe smart Trick of Roof Nuts That Nobody is Talking AboutThe Single Strategy To Use For Roof Nuts

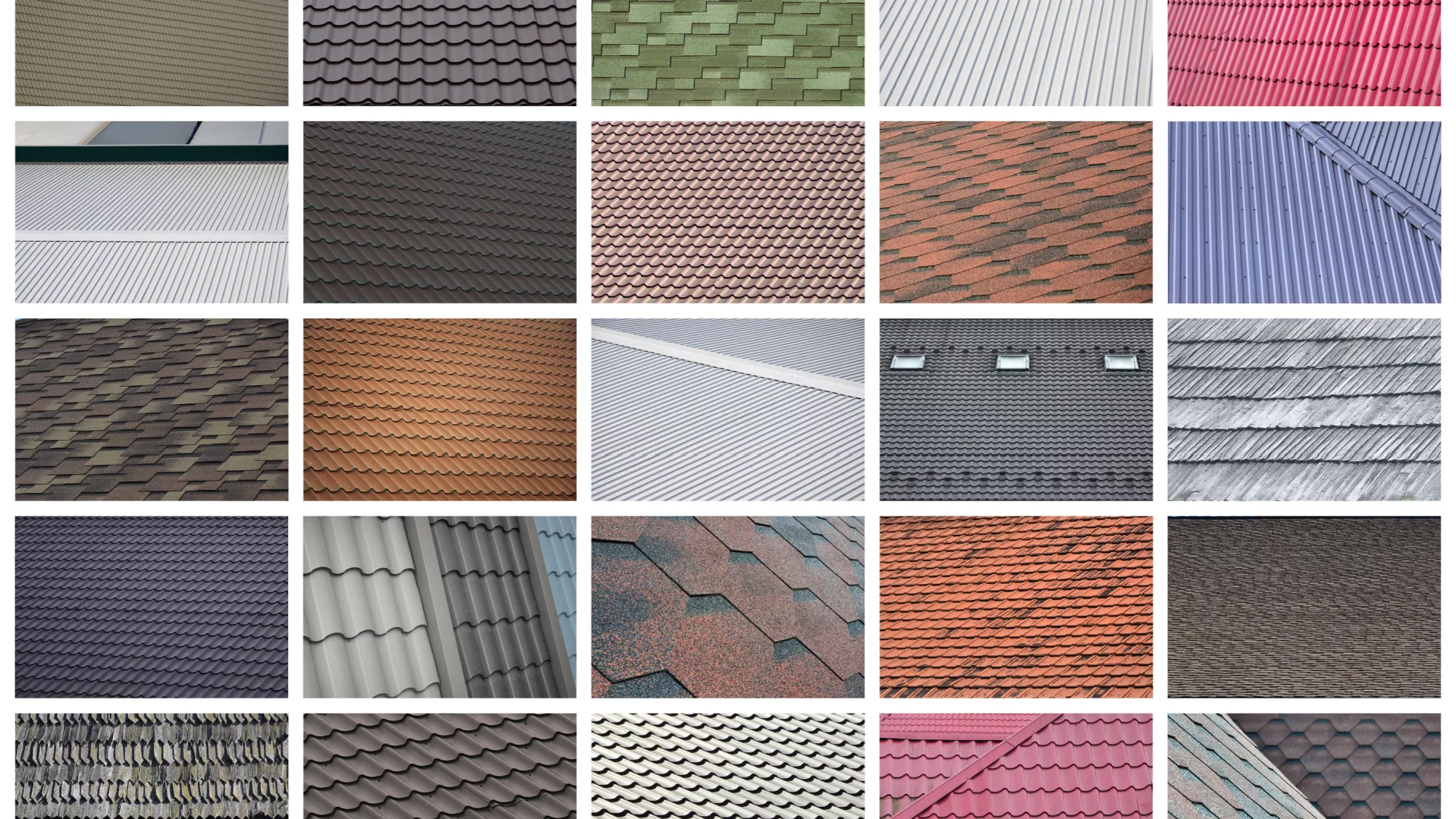

Made from an artificial thermoplastic layer integrated with enhancing scrim, TPO roof is set up making use of warm welding, producing a strong and sturdy bond with the roof covering deck. This approach of setup makes certain that TPO roofings can last approximately 25 years with proper care and upkeep. TPO roof covering material is available in different sizes, making it versatile for various level roofing applications. PVC roof covering is not advised for high slopes, as well as areas with hefty snowfall or freeze-thaw cycles. PVC roof covering incorporates longevity with convenience of setup, making it a prominent choice for various level roof covering applications.These systems, likewise referred to as developed roofing system, are composed of numerous layers of asphalt-impregnated roof covering felt and bitumen, developing a durable and leak-proof barrier versus the aspects. The top layer generally features carefully crushed rock granules, supplying a wear-resistant surface that can hold up against the roughness of time. The methodical application process of BUR assurances correct bond of each layer, therefore boosting the roofing's overall durability and longevity.

Everything about Roof Nuts

BUR is recognized for its cost-effectiveness, offering an affordable cost per year of predicted service life contrasted to other industrial roof covering systems. With a life expectancy ranging from 15 to three decades, BUR provides a dependable and durable roofing option for both domestic and business buildings. Its ability to manage various climate condition and its cost-effectiveness make BUR an appealing alternative for many property owners.

many thanks to the enhancement of special polymers. This asphalt-based material is customized to raise its flexibility and longevity, making it appropriate for a variety of environments and applications. Changed asphalt roof is made into rolls with either smooth or granulated surface areas, providing different options for different roof demands. There are various sorts of changed asphalt roof covering, with typical polymers such as atactic polypropylene (APPLICATION) and styrene butadiene styrene (SBS) used in the cap sheet.

Conversely, the cold adhesive technique involves applying a specially developed glue to the substratum before setting the modified bitumen sheets. There are likewise self-adhesive modified bitumen sheets that include a pre-applied glue layer, removing the need for open flames during installment. Each approach has its benefits, but all require skilled professionals to ensure optimal performance and durability

More About Roof Nuts

Steel roofing offers a number of benefits, consisting of resilience and durability. Metal level roofing can last approximately 35 years in optimal conditions, making it a trustworthy long-term investment. Additionally, steel roofings can promptly drop snow and ice, avoiding the accumulation that can cause damage. One of the significant downsides of steel roof is its higher initial cost compared to various other roof covering products.

Liquid roof has a reasonably simple application process that makes certain smooth, reliable insurance coverage. These systems can be put on a variety of surfaces, including metal, BUR, and single-ply membranes. The following subsections will certainly discover the various kinds of fluid coatings and the application procedure in information. There are numerous sorts of fluid layers used in roofing, each offering one-of-a-kind advantages: Silicone finishings master weather condition resistance and can stand up to ponding water without breaking down.

Roof Nuts for Beginners

This prep work phase is vital as it establishes the foundation for a smooth and resilient roof covering layer (Metal Roofing). As soon as the surface area is ready, the liquid layer is generally used utilizing spray tools or rollers for even insurance coverage.

The average life expectancy of a level roof covering is about two decades, which impacts the overall worth originated from the preliminary financial investment. Labor costs are a significant component of repair expenses and can considerably influence the lasting worth of a flat roof - https://www.slideshare.net/williamcaban16. Buying a durable and durable roof material can conserve money over time by decreasing the regularity and expense of repairs and upkeep